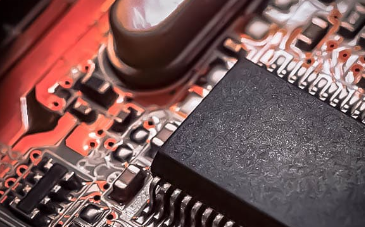

Complete Cleaning Solutions for the Electronics Industry

At Modern-Lab Chemicals Sdn. Bhd., we understand the critical importance of cleanliness and precision in the electronics industry.

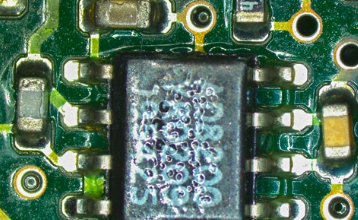

Contaminants can significantly impact product performance, reliability, and yield. That’s why we offer comprehensive cleaning solutions, including high-performance cleaning agents and advanced cleaning systems, designed specifically for electronics manufacturing and assembly processes.

Whether you need to remove flux residues, solder paste, adhesives, or general contaminants, our solutions ensure the highest standards of cleanliness while maintaining product integrity and compliance with industry regulations.

DCT Cleaning Solutions for Electronics

High quality water and alcohol based cleaning agents compatible with our cleaning systems; design and manufacture the highest quality cleaning machines with the longest warranty and widest range on the market; and develop hardware and software solutions for cleaning process control, including instrumentation and traceability.

1. Cleaning Agents

Including high-quality water-based and alcohol-based cleaning agents with the widest range on the market.

Water-Based

- All of our water-based agents have been developed for specific projects with the highest efficiency in mind for use on similar projects.

- Only using certified raw materials that comply with the most stringent RoHS Compliant, REACH SVHC legislation.

- Most water-based liquids are biodegradable in the natural environment.

Alcohol-Based

- All of our alcohol-based agents have been developed for specific projects with the highest efficiency in mind for use on similar projects.

- Only use certified raw materials that comply with the most stringent RoHS Compliant, REACH SVHC legislation.

Other Solutions

- Other products to solve problems with high concentrations of contamination in the cleaning or rinsing fluid.

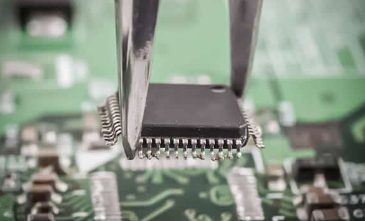

2. Advanced Cleaning Systems (Equipment)

Manufacture quality stainless steel cleaning machines, reliable and durable, with the widest range on the market and the longest warranty.

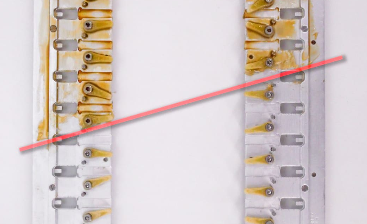

AirJet®

- AirJet® cleaning systems ensure direct contact of the solder frames with the cleaning agent throughout the cleaning process.

- Air bubbles agitate the fluid and ensure circulation.

- The frames are placed in baskets and must be manually transferred to the rinsing and drying chambers after cleaning.

- AirJet® cleaning systems are available with or without a semi-automatic manipulator, which is suitable for heavy baskets.

InJet®

- The InJet® series has many variants and possibilities of use.

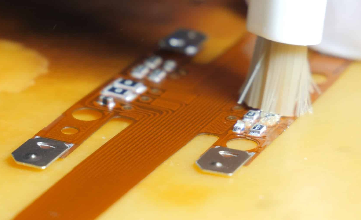

- It is most often used for cleaning applications in printing, but the ever-increasing requirements for the cleanliness of PCB boards from flux are used in PCB cleaning procedures.

- From single-chamber (batch cleaner) with vertical or horizontal spraying to multi-chamber (2,3, …) with both types of spraying.

- This allows you to customize the configuration exactly to your needs.

Sonix®

- Air-Bubble with ultrasonic technology achieves the highest efficiency of the cleaning process in specific applications. Such as cleaning: Coating frames, Parts of coating machines and Coated PCBs.

- It´s designed to clean all types of conformal coating from coating frames, masks, pallets, parts of the coating line, or PCB.

Applications in the Electronics Industry

Cleaning processes and cleanliness play a key role in the electrical industry, where even small amounts of contamination can have serious consequences for the performance and safety of equipment.

DCT provides innovative cleaning solutions that help electrical companies to achieve the highest standards of cleanliness and performance.

|  |  |

| Stencil + Misprint + Squeegee | PCBA Cleaning | Maintenance Cleaning |

|  |  |

| Conformal Coating Cleaning | Manual Cleaning | Under-stencil Cleaning |

|  |  |

| ESD boxes and magazines | Double-side Misprints | Manual PCB Cleaning |

|  |  |

| Manual Cleaning of Reflow Ovens and Waves | Coated PCBAs | Cleaning PCBA from Dust and Rust |

| ||

| Coated Frames and Parts of Coating Machines |

Why Choose Our Cleaning Solutions?

- Complete cleaning solutions - We can offer complete cleaning solutions for all existing applications.

- Quality of cleaning systems - We offer cleaning systems exclusively in stainless steel because it has long-term advantages.

- Pure quality of cleaning agents - We care about the functionality of the cleaning chemistry, but also about ecology.

- Technical and economic improvements - With every project, our greatest motivation is to bring the customer a better technical and economic solution.

- Development and customization - Continuous R&D, we are moving forward and responding to developments in the electronics industry.

- Worldwide Distribution - We give customers the opportunity to actually test the cleaning solution.

- Direct service Support - For us, service support does not end with the installation, it begins.

Contact Us Today

Looking for reliable and effective cleaning solutions for your electronics manufacturing process? Contact us today learn more about our complete range of cleaning agents and systems.

Our team is ready to assist you in optimizing your cleaning process for enhanced productivity and product quality.